TYRETHANE Screen Media

Tyrethane products come from the only polyurethane plant in North America that blends its own material, which is critical to quality control. Tyrethane is tested daily for tensile, elongation, taber abrasion and split tear to ensure its chemical composition is correct for the heavy aggregate and mining applications it must stand up to. All products perform well in wet or dry applications. Tyrethane is available in both hooked sections and modular panels, so there’s never a need to make any changes to a deck set-up.

TYRETHANE SCREEN MEDIA

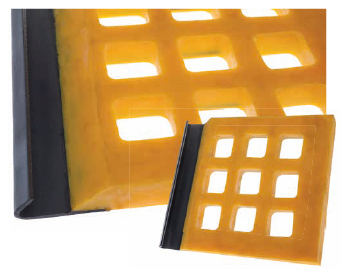

TY-MAX

CUT SIZE RANGE

Ty-Max Hooked offers the wear life of a polyurethane panel in a hooked section, so no deck conversion is required.

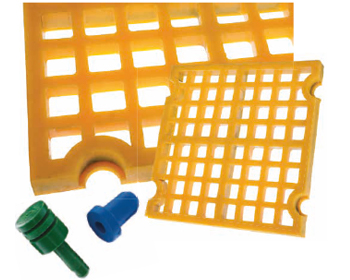

TY-DECK

CUT SIZE RANGE

Ty-Deck modular panels, just like Ty-Max, are poured open cast and permanently harden when cured to maintain their chemical properties, so each resists wear and tear.

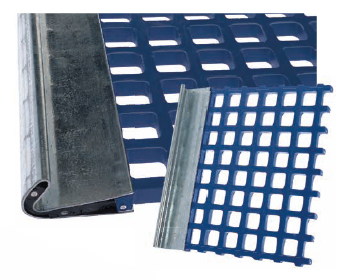

TY-WIRE

CUT SIZE RANGE

The jump from woven wire cloth to polyurethane can be big – the weight difference alone can signifi cantly alter the performance of your vibrating screen and affect your product quality. That’s where Ty-Wire offers greater open area than polyurethane and actually weigh less than woven wire cloth.